Read in : தமிழ்

India aims to reduce imports of fossil fuels by achieving 20% ethanol blending with gasoline from April 2023. A nationwide rollout is planned from 2025-26. At present, India’s ethanol production capacity is 426 crore litres from sugarcane-based distilleries and 258 crore litres from grain-based distilleries. By 2027, the ethanol market in India is estimated to reach Rs.40,593 crore. At present, India is the second largest importer of US ethanol for industrial purposes. The centre has also cut Goods & Service Tax (GST) on ethanol meant for the Ethanol-blended Petrol (EBP) programme from 18% to 5%.

To ensure a $1 trillion economy for Tamil Nadu by 2030, multiple efforts are underway to tap the strategic advantages in emerging industries with the timely launch of new policies for facilitation and promotion of investment. The latest one is the Tamil Nadu Ethanol Blending Policy 2023 to generate clean energy from diverse foodgrains other than sugarcane. The policy aims to attract Rs.5000 crore in new investments to establish molasses/foodgrain-based ethanol plants with a production capacity of 130 crore litres.

Tamil Nadu is already a major automobile market with the third largest vehicular population in the country. The State’s petrol requirement is estimated to increase to 474 crore litres by 2024-25. According to the state ethanol policy, Tamil Nadu stands third in the consumption of Motor Spirit (MS) petrol after Uttar Pradesh and Maharashtra with a consumption of about 2.7 million metric tonnes (3.8 billion litres) in 2021-22.

The new state ethanol blending policy rightly recognises that “with transportation sector accounting for nearly one-fourth of GHG emissions and considering the projected robust growth of the State’s vehicular fleet, there is an immediate need to transition to alternate cost-effective green fuel that mitigates climate change”.

The National Policy on Biofuels (2018), emphasises the production of ethanol from a variety of feed-stock including agricultural residue (rice straw, cotton stalk, corn cobs, saw dust, bagasse etc.); starch containing materials such as maize, cassava, rotten potatoes; damaged food grains apart from sugarcane and other sugar containing materials such as sugar beet. One such major foodgrain identified as feedstock in the state ethanol policy is tapioca, which would also benefit farmers of the starch-rich tuber.

Despite Tamil Nadu’s surplus production of tapioca, an ideal feedstock for bioethanol, the state has no plants to use the starch-rich crop

At present Tamil Nadu does not have a significant presence on ethanol production and gets its requirement from other states like Maharashtra and Karnataka. The state has 12 molasses projects with an installed capacity of just 17.4 crore litres per annum. Thus, there is huge scope for establishing bioethanol plants for food grains based like tapioca crop. Tapioca with its high starch content (25 to 35%) and ability to grow under low management conditions has been globally recognised as a potential feedstock for bioethanol production.

The state ethanol policy highlights that Tamil Nadu accounts for about 80% of the total acreage under tapioca in the country producing 38.93 lakh metric tonnes from over 91,506 hectares. The tuber is mainly cultivated in Salem, Namakkal, Erode, Cuddalore, Villupuram, Dharmapuri, and Kanyakumari districts. Not surprisingly, the over 800 starch and sago factories, spread over Salem, Erode, Namakkal, and Dharmapuri are flourishing.

Also Read: Ethanol blending: Thanjavur awaits this green revolution

Kerala, Tamil Nadu, and Andhra Pradesh account for about 96% of the area and 98% of tapioca production in India. While the tuber has been largely used as raw material for starch extraction, Kerala has tapped into the export markets for value-added tapioca products. The processed tapioca with masala from Kerala is in great demand overseas including the US, Australia, and New Zealand. The major countries importing Indian tapioca are the US, Saudi Arabia, UAE, Nepal, and the Netherlands.

Given that Tamil Nadu has not diversified into tapioca-based products for export, a recent report stated that its surplus production of over a million tonnes in a year can be used for the generation of bioethanol. Though, the CTCRI in Thiruvananthapuram has developed novel enzyme technology for the production of ethanol from tapioca starch/flour, the technology is yet to be implemented for a pilot study prior to being scaled up. While a plant set up in Palakkad in the late 1990s failed to scale up, Kerala government has allocated Rs. 2 crore for the research and the production of ethanol from tapioca in its 2022 budget. If the proposal takes off it will help the state’s farmers get a remunerative price for the tuber which has seen a glut with widespread cultivation under the Subiksha Keralam project.

The Tamil Nadu Agriculture University (TNAU) established the Tapioca and Castor Research Station in Yethapur near Salem with the stated objective of “development of post-harvest technology, value added products and bio-fuels survey, monitoring and management of major pests”. However, it seems the Research Station has not done any significant work in the area of tapioca value addition.

Other states have stolen a march over Tamil Nadu. Andhra Pradesh and Haryana each have 15 foodgrain-based ethanol plants, Maharashtra has 28, Punjab 18, Karnataka 6 and Bihar 5

Tamil Nadu’s ethanol blending policy aims “to maximise its value addition to the State’s natural resources by promoting indigenous ethanol production based on existing locally available agrocentric resources, expansion of these resources as well as utilisation of surplus and damaged produce.” Further, the policy state that “Tamil Nadu to augment biofuel production within the State using indigenous sources which could partly insulate the import price shocks, address the pollution concerns and enhance agricultural output and its utilisation.”

The major lacuna in the Tamil Nadu Ethanol Blending Policy 2023 is that it has not identified specific indigenous technologies for foodgrains-based ethanol production. The only existing method of ethanol production is from molasses.

Also Read: Why does PMK see red in NLC expansion plan?

Other states have stolen a march over Tamil Nadu in this regard. Andhra Pradesh and Haryana each have 15 foodgrain-based ethanol plants, Maharashtra has 28, Punjab 18, Karnataka 6 and Bihar 5. Given its agri-production base, the state government should have initiated a scientific study to identify indigenous technologies to produce ethanol before the announcement of the policy. In this absence, the stated objective of improving farmers’ incomes through ethanol blending, reviving the sugar industry, and making the State an investment hub for cost-effective green fuels lacks substance.

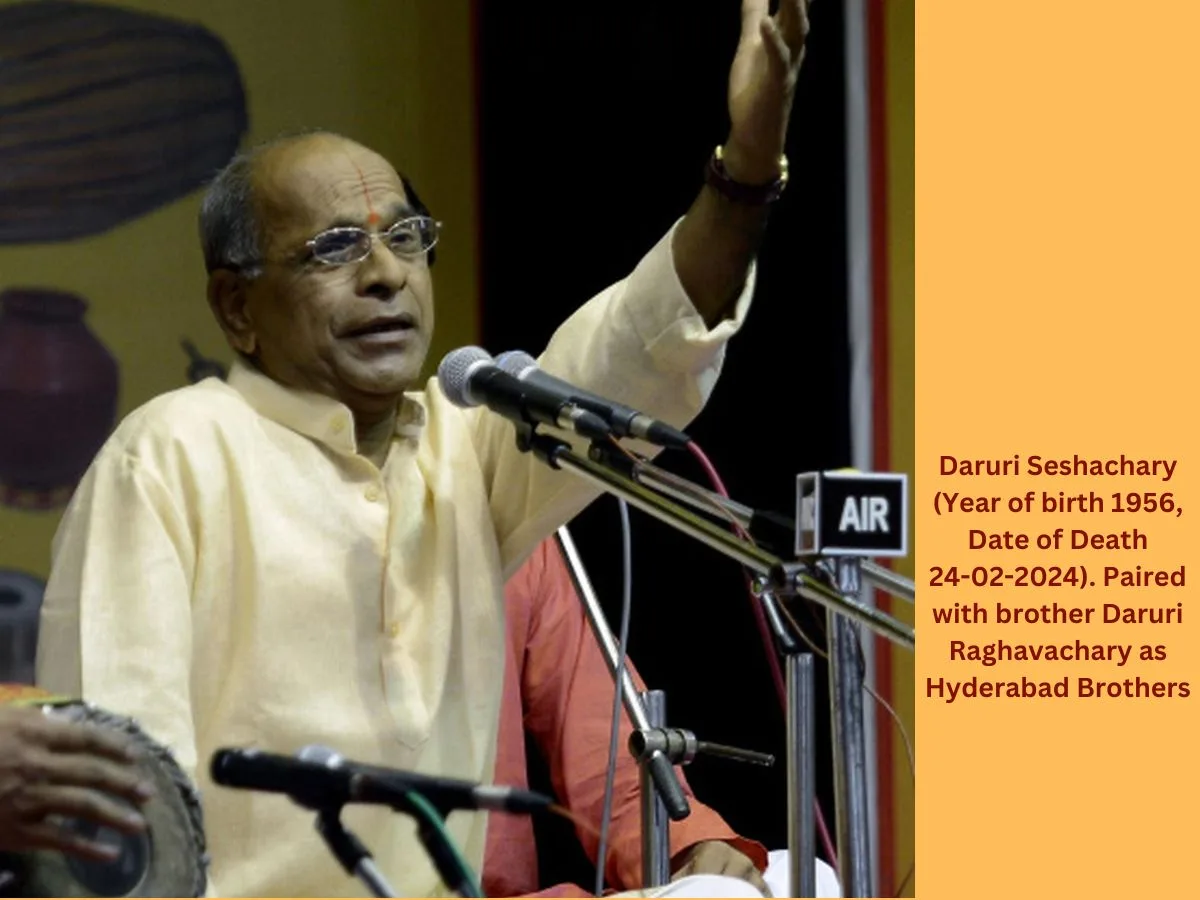

(The author is an economist and public policy expert)

Read in : தமிழ்